Are you ready for Industry 4.0? You better be

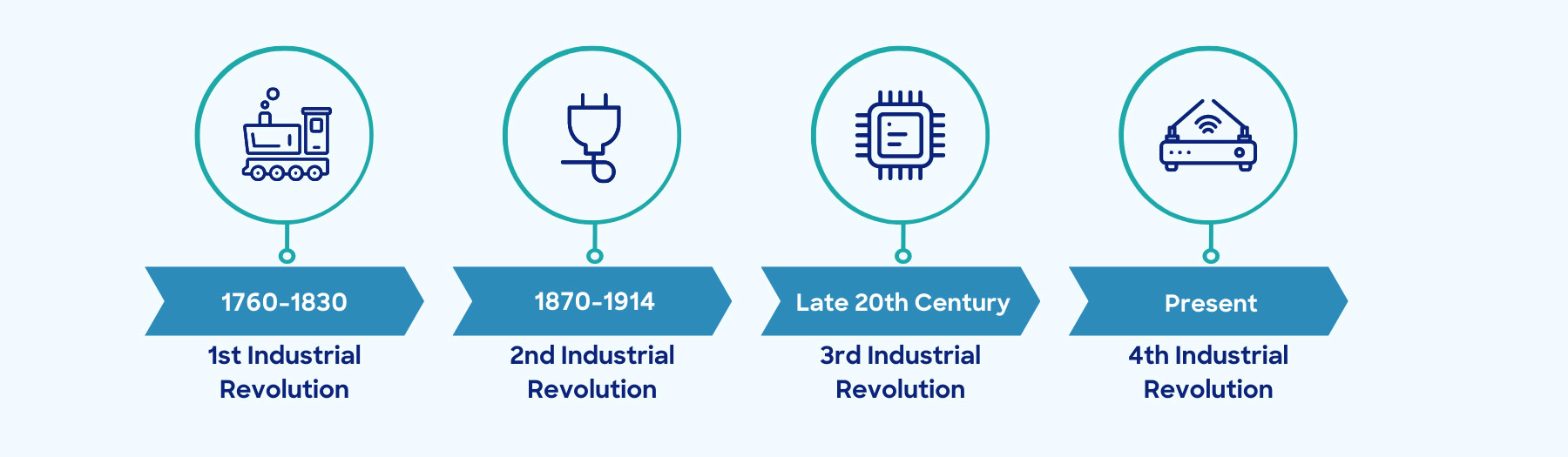

It started from steam power, then came electricity and computers. Now, the 4th industrial revolution dawns with the rise of AIs. Welcome to “Industry 4.0.”

Industry 4.0 definition

Many experts say that the Fourth industrial revolution, dubbed “Industry 4.0,” is the next big thing. But when you look around and see self-driving cars, augmented reality, cloud technologies, and smart systems, you’ll realize that it’s not just coming soon. The future has already begun.

Industry 4.0 is a term coined to describe the shift of industries from analog to digital, where businesses rely on smart technologies, big data, and Artificial Intelligence to produce, manufacture, and deliver goods and services.

It is called the Fourth Industrial Revolution to allude to the three landmark innovations that happened before – the rise of steam and water-powered mechanization, the rise of electricity and mass production, and the rise of computers and IT systems.

Industry 4.0 uses existing computer and IT systems to digitize, connect, and automate manual and analog processes, making it easier for businesses to gather and analyze big data and strategize for growth.

Industry 4.0 Technologies

One of the most prominent Industry 4.0 technologies is Artificial Intelligence, which refers to how computer systems imitate how humans think. AI-powered machines and systems can process information, recognize complex patterns, form conclusions, and make scientific recommendations.

Other groundbreaking Industry 4.0 technologies include virtual and augmented reality, which can simulate the real world, and the Internet of Things, which is fundamentally a system of complex processes across distances connected and automated through the internet.

A brief history of innovations

The First Industrial Revolution began in the mid-18th century in Great Britain when scientists found a way to harness the power of steam and water. The discovery led to the creation of machines that optimized labour that was previously done manually by people and animals.

Steam and water engines reduced the toll of manual physical labour for the workers, which enabled mass production of manufacturing goods. This era, which lasted until around 1830, gave rise to steam-powered trains and ships, spinning machines for weaving, the power loom, and more.

The Second Industrial Revolution, meanwhile, was marked by mass production and industrialization. It was an era where humans found a way to use oil, gas, and electricity to power bigger machines for manufacturing and innovations in communication.

Some of the technologies born out of the Second Industrial Revolution were lightbulbs, radio technology, and even telegraphs and telephones – predecessors of the internet and the gadgets that we now know as smartphones.

The Third Industrial Revolution peaked in the late 20th century, when computer technologies emerged, rapidly advancing the progress in telecommunications. The era connected the world through wired and wireless systems and, eventually, through the internet.

Adapting to Industry 4.0: How to thrive in a new world

Some businesses brush off today’s emerging technologies as “excessive” and “fancy,” not realizing how much help they can get from these tools and how these generational innovations are slowly becoming the new normal.

Digital grammar correcting tools have replaced proofreaders, digital shops are slowly replacing physical shops, bots are answering customer queries, and you can now make payments through your phone – the future is already here. The game is “adapt or lose.”

But how does one adapt? Shifting to new technologies and systems can be challenging, especially for small and medium-sized businesses. But change does not have to be instant. Change should be a process where you can strategize and set objectives.

Here are some ways to begin your digital transformation journey in the Industry 4.0 era.

Check your readiness

Assess your business operations and determine aspects and functions that can be digitalized easily and require long-term planning. Run an audit of your tools and identify the upgrades you need to do. Understanding your current capabilities and needs will give you profound insights into how you can begin adapting to the new era of doing business.

Create a digital roadmap

Draft a digital roadmap using information from the assessment you just made. It will allow you to set short- and long-term objectives and strategize accordingly. A clear and comprehensive roadmap will help you streamline the processes and steps you will have to take during the long digital transformation journey.

Hire tech professionals

New technologies require new skills, which means hiring experienced experts from different fields to help you carry out specific processes required in digital transformation. If hiring would be costly, especially in the early stages of business, you may want to assess your employees and identify people who can switch to different roles by upskilling.

Invest wisely

In the digital transformation process, you will come across tools and software that promise increased efficiency in certain areas and overall improvement in business operations. But not all of them will fit what you need. Take time to assess the market tools and software, and ensure they align with what you want to achieve.

Play the long game

Digital transformation is a long game. Because Industry 4.0 has just begun, expect more innovations to come as people figure out how today’s technology can fit into the way we do business. While it’s good to have short-term goals, always make sure that you are ready for any significant changes on the horizon when new inventions or discoveries emerge.

Future-proof your business with outsourcing

Certain realities in today’s world can make digital transformation a real challenge. One is the lack of skills available, especially in IT and technology, because of a global talent shortage.

There is also a growing concern about data and IT security with the rising number of cyberattacks in recent years. Falling victim to cyberattacks can disrupt operations for longer periods and stunt growth, which is why businessmen are wary about shifting to digital.

Lastly, the cost of implementing massive change in an organization is huge. Investments may not deliver results immediately, and uncontrollable factors, such as a country’s economy, can affect short- and long-term targets.

In the face of these challenges, outsourcing can help you in many ways. For one, it allows businesses to address the huge talent gap by providing access to highly skilled professionals across the world at a much lower rate.

Top outsourcing markets like the Philippines have a deep pool of IT and technology experts that can help you in your digital transformation. And because the cost of living in the Philippines is lower, businesses can get experts and get huge savings on labour costs.

Outsourcing can also give you an edge when it comes to tools and technology. Aside from talent, providers also offer access to a wide range of technology through a network of partners and suppliers that can optimize business operations.

It is also part of the job of the outsourcing providers to upgrade their own data and IT security tools and policies due to the global nature of their work. Partnering with an outsourcing provider means accessing these enterprise-grade security systems that can be costly if acquired independently.

Outsourcing offshore can help your business sustain efficiency whilst implementing drastic changes in your organization. It can even introduce you to new markets, help you create a global presence, and give you a competitive edge.

Adapting to the Industry 4.0 era may be hard, but it certainly helps if an established and experienced outsourcing provider has your back.